Minimize rig time with the right casing and tubing running systems:

SAMEN casing and tubular running services are the right choices for efficient casing and tubular running. When you need expert handling of exotic chrome tubular, for any job from the simplest to the most challenging, we have the answer that minimizes rig time.

The field-proven, fully integrated SAMEN ChromeMaster™ chrome running system enables handling and makeup of chrome tubular from 2-7/8 in. to 14 in. The system does not leave die marks that damage chrome tubular and degrade performance.

For accurate torque measurement, the SAMEN torque-turn systems—including the SAMEN Salvo™ MK V monitoring system—minimize cost by ensuring the correct torque is applied and faulty connections are immediately detected. Our high-value services are part of a complete suite of the casing and tubular running services. The safer SAMEN Derrickman™ hydraulically powered stabbing arm is operated remotely from the rig floor; the stabber’s injury risk is completely eliminated.

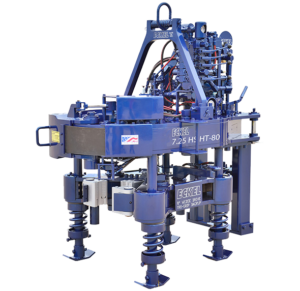

Hydraulically powered casing and tubing tongs:

We have the most comprehensive and efficient suite of casing and tubing tongs. These tong systems include self-contained hydraulic power units custom built and certified to the highest industry standards. Tong systems cover a wide range of sizes and torque capacities from small tubing through a large-diameter casing. Integrated hydraulic backups maximize accuracy and efficiency.

The SAMEN Leadhand™ tong positioning system moves the hydraulically powered tongs to and from the wells centerline. The system enables one-man tong operation.